In fast-paced industries where every second counts, workplace safety can sometimes feel like a moving target. From construction sites to manufacturing plants and marine operations, safety protocols must evolve to match the complexity of modern projects. However, with the right tools, safety doesn’t have to be a burden—it can be seamlessly integrated into daily operations.

This is where the combination of Electronic Permit to Work (E-PTW) systems and Building Information Modelling (BIM) steps in, transforming how we approach workplace health and safety. These two systems, each powerful in their own right, create a synergy that enables better hazard management, coordination, and compliance. Below, we’ll explore five ways this integration can elevate safety management to the next level.

Real-Time Hazard Visualization for Smarter Decision-Making

Imagine knowing exactly where potential hazards lie before your team steps foot on-site. That’s what the integration of E-PTW and BIM can offer.

When you merge BIM’s 3D modeling capabilities with the meticulous control of E-PTW, you get a real-time visualization of the site and its risks. This allows safety managers to see the full picture—literally—before issuing permits. Instead of working off static paper plans, you’re equipped with a living, breathing model of the project site that evolves as the work progresses.

Why This Matters:

- Identify risks before they become incidents: By visualizing the work environment in 3D, potential hazards such as equipment clashes or proximity to hazardous materials are identified early.

- Informed permit decisions: The E-PTW system ensures that no high-risk task begins without the necessary precautions, and BIM helps verify that those precautions are sufficient based on the actual site conditions.

This level of visibility makes it easier to make smart, informed decisions that prioritize safety without slowing down progress.

Enhanced Communication Between Teams on Complex Projects

On large projects with multiple teams, communication can be a challenge. Whether it’s contractors working alongside in-house teams or simultaneous tasks requiring different safety protocols, a breakdown in coordination can lead to dangerous situations.

With the integration of E-PTW and BIM, everyone from site workers to project managers can access the same up-to-date information. Safety measures, permits, and work areas are visible in the 3D model, and any changes are reflected in real-time.

Key Benefits:

- Clash detection: BIM helps ensure that tasks requiring permits, like electrical work or hot work, don’t clash with other ongoing activities, reducing the risk of accidents.

- Clear responsibilities: Everyone can see who’s responsible for what, when, and where, preventing misunderstandings that could lead to unsafe conditions.

When teams have access to shared, clear information, confusion is reduced, and everyone is on the same page. This integration fosters a culture of transparency and coordination, making safety a collective effort.

Effortless Compliance and Traceability

Keeping track of permits and ensuring regulatory compliance can be overwhelming, especially when projects span months or even years. The combination of E-PTW and BIM creates an effortless audit trail that not only makes compliance easier but also provides peace of mind.

How It Works:

- E-PTW automatically records every detail of the permit process—from risk assessments to approvals—so that all documentation is readily available.

- BIM overlays this data onto a 3D model of the project site, offering a visual context to every permit issued.

This integrated system ensures that safety protocols are adhered to every step of the way, and it also provides a detailed record should an incident occur or an audit take place.

Why This Is Crucial:

- Clear documentation: If you need to show regulators how safety procedures were followed, this system provides an easily accessible, time-stamped record.

- Simplified audits: Auditors can trace every permit back to its original assessment and see exactly how it was applied on-site, reducing the time and effort required to prove compliance.

Minimized Delays and Streamlined Workflows

While safety should never be compromised, let’s face it—traditional safety processes can slow things down. Waiting for permit approvals, especially when dealing with paper-based systems, can introduce frustrating delays. Integrating E-PTW and BIM speeds up these processes without sacrificing safety.

Efficiency Gains:

- Automated permit approvals: E-PTW automates much of the permit workflow, ensuring that high-risk tasks are flagged and reviewed quickly. BIM supports this by giving safety officers an immediate visual overview of the worksite, making it easier to approve permits when it’s safe to do so.

- Real-time safety updates: If the site conditions change—whether it’s due to weather or new construction progress—BIM can alert the E-PTW system to suspend or revise permits as needed, preventing unsafe work from continuing.

Fewer delays mean projects can stay on schedule, while still ensuring that safety isn’t compromised. It’s the best of both worlds—efficiency without risk.

Proactive Risk Management to Prevent Accidents

Safety isn’t just about responding to incidents—it’s about preventing them from happening in the first place. The integration of E-PTW and BIM enables a proactive approach to risk management that’s hard to achieve with traditional methods.

Proactive Safety Features:

- Simulate potential risks: BIM allows safety teams to simulate different scenarios, such as crane operations or hazardous material handling, to identify risks before any physical work starts. E-PTW then ensures that permits for these tasks are issued only after all risks are mitigated.

- Continuous risk monitoring: As the project progresses, both systems provide real-time data on site conditions. This means risks are monitored continuously, and safety measures can be adjusted before something goes wrong.

By predicting potential hazards and making data-driven safety decisions, accidents can be significantly reduced. This integrated approach creates a culture of preventative safety, where risks are managed before they ever materialize.

How Can PEER Help?

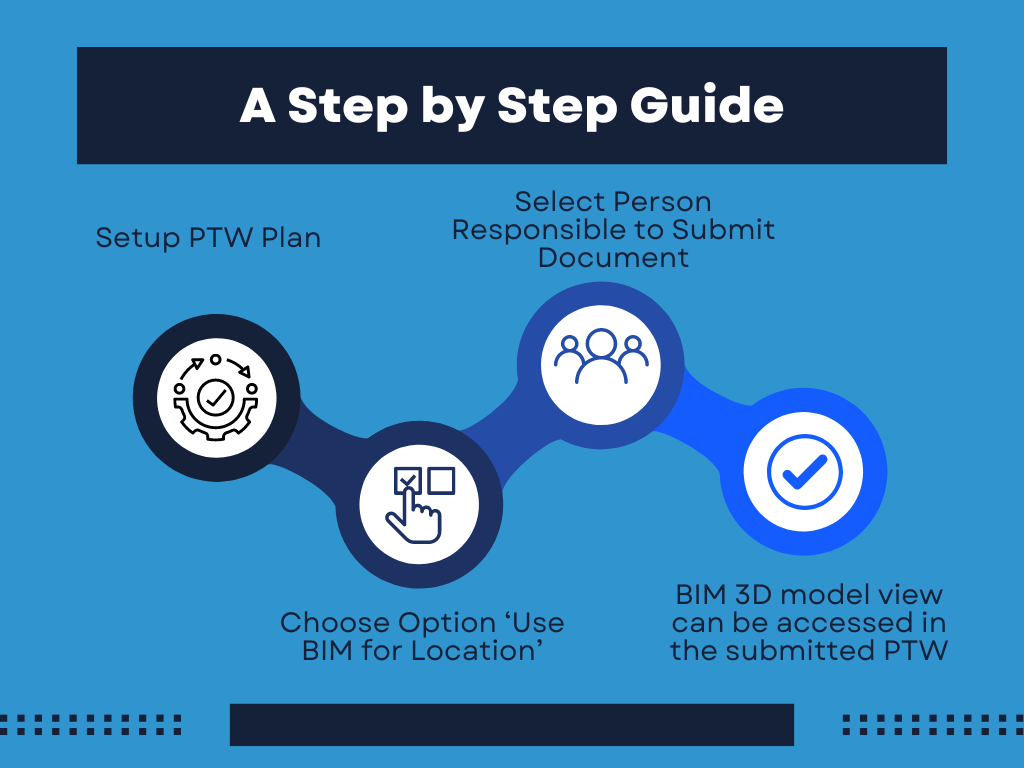

PEER enhances workplace safety by integrating Electronic Permit to Work (E-PTW) and Building Information Modelling (BIM). This combination provides real-time hazard visualization, allowing teams to identify risks before work begins and make informed safety decisions. Additionally, PEER streamlines compliance by automatically tracking permits and ensuring all safety measures are documented, ultimately minimizing delays and preventing accidents.

Conclusion

When workplace safety is streamlined, everyone wins. The integration of E-PTW and BIM brings together the best of both worlds—enhanced safety controls and real-time project insights. From proactive risk management to seamless communication and efficient workflows, this combination helps organizations reduce risks, prevent accidents, and stay compliant, all while maintaining project momentum.

For those working in industries where safety is non-negotiable, integrating E-PTW and BIM isn’t just a nice-to-have—it’s becoming a necessity. As technology continues to evolve, these tools will play an increasingly critical role in shaping safer, more efficient workplaces.

By adopting these technologies, companies are not only protecting their workforce but also future-proofing their operations against the ever-changing landscape of workplace health and safety.