Falls are the leading cause of workplace fatalities, accounting for over a third of all annual deaths. While these fatal accidents are most common in high-risk sectors like construction, they can also occur in various other industries where employees might work at heights, such as on ladders or roofs.

Work | Examples |

Work in an elevated workplace. |

|

Work near an open edge. |

|

Work near a floor opening. |

|

Work on a fragile surface. |

|

Any other work environment (whether above or below ground) that poses a fall-from-height or fall-into-depth risk. | N.A. |

Laws and Industry Standards

As an employer, you are expected to comply with Singapore’s WSH laws. You should pay particular attention to:

- WSH (Work at Heights) Regulations

- WSH (Risk Management) Regulations

- WSH (Incident Reporting) Regulations

You should also observe relevant industry standards, such as:

- Code of Practice for Working Safely at Heights (PDF);

- Code of Practice for Working Safely at Heights – Mandarin (PDF); and

- Code of Practice on WSH Risk Management (PDF).

Please refer to the WSH (Approved Codes of Practice) Notification (PDF) for the full list of approved Codes of Practice.

Preventing Falls from Height

As an employer, you should:

- Provide safe and proper access to and egress from heights for employees.

- Install adequate fall prevention/protection systems such as guard rails, scaffolds and covers for openings.

- Establish safe work procedures for various work at height (WAH) activities.

- Provide individual fall arrest system (e.g. safety harness) for employees working at height.

- Educate employees on the proper use of fall arrest devices (e.g. securing to a suitable anchor point).

- Implement a travel restraint system to prevent employees from reaching an unguarded edge.

- You should also develop and implement a fall prevention plan and a permit-to-work system.

Fall Prevention Plan

A fall prevention plan (FPP) is a site-specific plan to eliminate or reduce the risk of falls.

As an occupier of a worksite, shipyard or premise for bulk storage of toxic or flammable liquid, you are required to implement an FPP in your workplace where WAH is carried out. You are also required to implement an FPP if your factory:

- Manufactures or processes petroleum and petrochemicals, and their products;

- Manufactures chlorine, fluorine, hydrogen fluoride or carbon monoxide;

- Manufactures synthetic polymers;

- Manufactures pharmaceutical products or their intermediates;

- Manufactures semiconductor wafers; or

- Employs 50 or more people.

Your FPP should include (but not limited to) the following components:

- Fall prevention policy;

- Responsibilities;

- Risk management and control measures;

- Safe work procedures;

- Use of personal protective equipment;

- Inspection and maintenance;

- Training;

- Incident investigation; and

- Emergency response.

Permit-to-Work System

A permit-to-work (PTW) system is a necessary documented process to be implemented for hazardous WAH where employees could fall more than 3 metres either from an elevated site or into a depth.

You must have a PTW system for hazardous WAH if your workplace is a factory as defined under the Workplace Safety and Health or check also PEER PTW for Work at Height Operation

Reference: The Workplace and Safety (WSH) Council

Open edge of building under construction without proper barricade

Open edge of building under construction without proper barricade

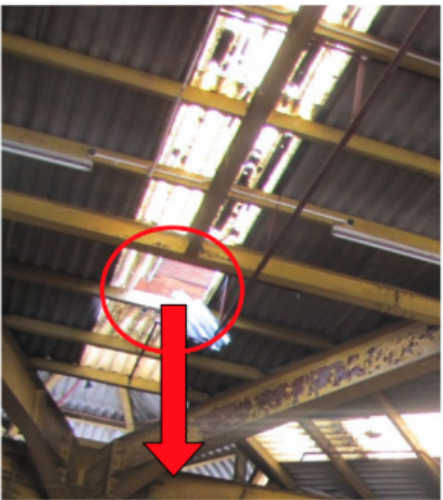

Fragile roof skylight

Fragile roof skylight