Risk Management (RM) is a systematic way of Identifying, assessing, controlling and monitoring workplace safety and health (WSH) risks associated with any work activity or trade. You need to communicating these risks to employees, contractors and other relevant parties.

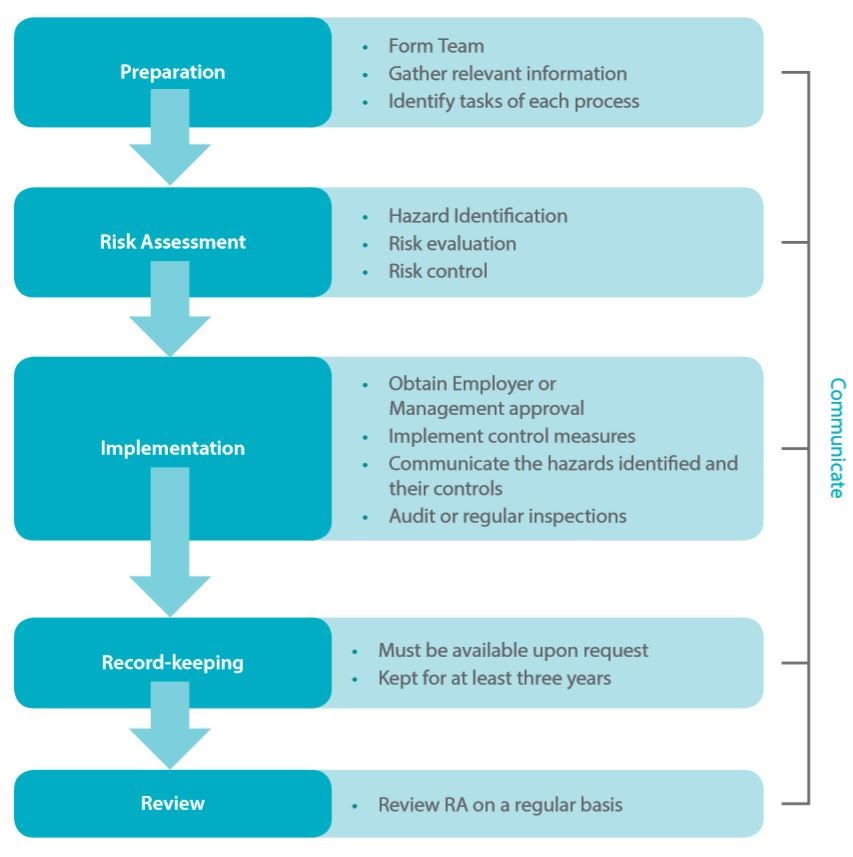

The main components of RM include preparation, risk assessment, risk control implementation, record-keeping and review. Refer to the Code of Practice on WSH Risk Management (PDF) for more information.

Conducting Risk Assessments

Risk Assessments

Risk assessments (RAs) are a key component of risk management. As an employer, self-employed person, or principal, you are required to conduct RA and implement risk control measures before any new work starts.

You are also required to review RA at least once every three years, or:

- Upon any accident, incident, near miss or dangerous occurrence.

- When there is any significant change in work process or activity.

- When new information on WSH risks is made known.

How to Prepare for Risk Assessments

Before you conduct RA, you need to:

- Appoint a multidisciplinary Risk Assessment Team.

- Gather relevant information (e.g. list of work activities in the process).

- Identify the sub-activities of each work activity.

How to Conduct Risk Assessments

Conduct RA through the following steps:

Hazard Identification

To identify hazards, you can use the Risk Assessment Form or a similar document. If you are using the RA form, break down your work activity into sub-activities and use the “Hazard” column to record hazards.

You may walk around your workplace to observe processes, operations and work activities. Look out for safety and health risks that could harm your employee or affect their health and well-being. You should consider the following hazard categories:

Hazard category | Example |

Physical |

|

Mechanical |

|

Electrical |

|

Chemical |

|

Biological |

|

Psychosocial |

|

Work-related Factors | Examples |

Proximity of | Employees doing assembly work next to noisy stamping machines may be exposed to excessive noise too. |

Compatibility of work | Hot work and spray painting are incompatible work activities. There is a fire risk if they are carried out near to each other. |

Non-routine work activities and situations | Maintenance work and shut-down operations may introduce additional hazards that have not been identified as part of routine work activities. |

Work environment | Working outdoors during adverse environmental conditions such as haze may cause respiratory problems among employees. |

Risk Evaluation

After you’ve identified the hazards, you need to evaluate the risk level of each hazard based on the:

- Likelihood of the hazard causing harm; and

- Severity of the harm.

When evaluating the risks of health hazards such as toxic substances and noise, you must conduct hygiene monitoring to estimate employees’ exposure levels to these hazards, and compare their exposure levels with established permissible exposure limits. Find out more about preventing chemical hazards and noise-induced deafness.

After you’ve evaluated the risks of each hazard, you should take appropriate action to eliminate or minimise those risks. Reasonably practicable measures should be taken to protect people from harm.

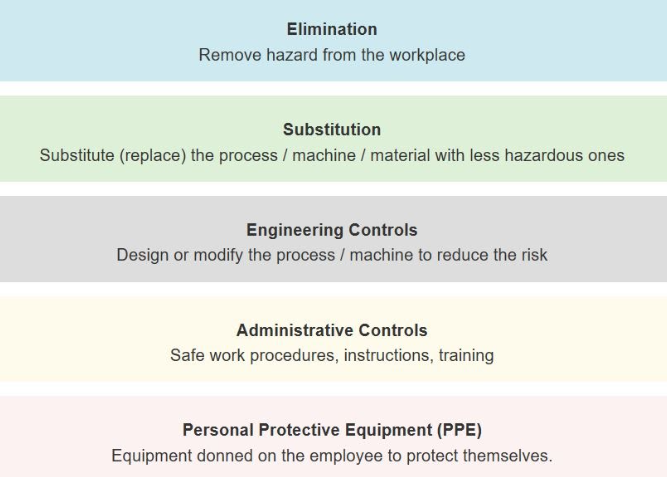

You should select your risk control measures based on the Hierarchy of Control. Upstream risk controls (e.g. elimination, substitution and engineering controls) are more effective in reducing or controlling risk, and should be considered first.

You should consider using a combination of control measures from the Hierarchy of Control as no single measure is usually sufficient to control the risk. For example, engineering controls need to be implemented together with administrative controls such as training and safe work procedures to address the hazard sufficiently.

Personal protective equipment (PPE) should be explored only after upstream risk controls have been considered, as a short-term contingency during emergency, maintenance, repair or as an additional protective measure against residual risks. The effectiveness of PPE depends greatly on whether it is chosen and fitted correctly, worn at all times and maintained properly.

For hazards that cannot be controlled immediately, interim control measures should be implemented while establishing longer term measures to reduce the risk level. Work should not start if the risk remains high.

Reference: The Workplace and Safety (WSH) Council