Worker’s Safety Guide for Rigger and Signalman

In This Free Course, You Will Learn How To

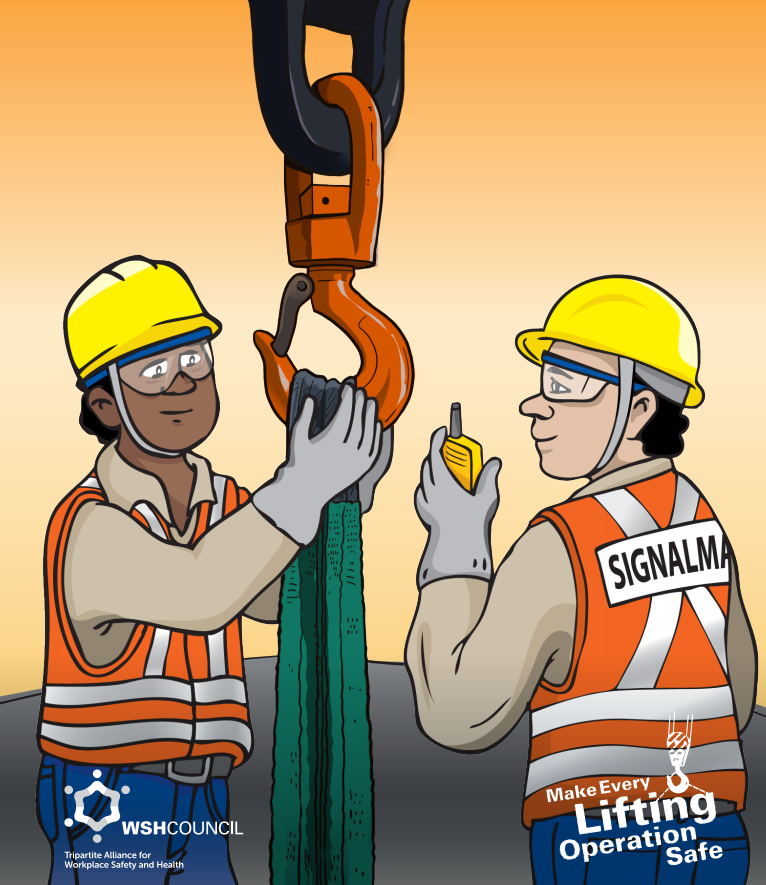

- Proper attire for riggers and signalman includes helmets, gloves, steel-toed boots, high-visibility clothing, and fall protection gear to ensure safety on site.

- Rigging involves securing loads, inspecting equipment, and ensuring safe lifting practices. Riggers must ensure equipment is in good condition and loads are properly secured.

- Good rigging practices include using the right equipment and proper load balancing, while bad practices, such as using damaged equipment, can lead to accidents.

- Inspecting hooks and shackles for cracks, corrosion, or wear is crucial to maintaining safety during lifting operations.

- Wire ropes can wear out through fraying, kinking, and corrosion. Regular inspections help identify issues early to prevent accidents.

- Signalman ensure safe lifting by directing crane operators and riggers. Clear communication through hand signals is essential.

- Using proper crane hand signals ensures effective communication, especially in noisy environments.

- Good communication practices, such as eye contact and clear signals, are essential for safe lifting operations.