パワープレスおよびプレスブレーキの安全な使用に関する技術アドバイス

この無料コースでは、次のことを学びます

- パワープレスとプレスブレーキの安全対策と操作要件の概要を理解します。

- パワープレス操作における安全プロトコルを理解するために不可欠な重要な用語と定義について説明します。

- パワープレスとプレスブレーキに関連する一般的な危険性について、リスク要因とその影響に重点を置いて学習します。

- 効果的な対策を通じて機械式パワープレスを保護することに重点を置いた設計およびエンジニアリング制御について説明します。

- パワープレスの設置、移設、変更時の安全上の考慮事項についての洞察を得ます。

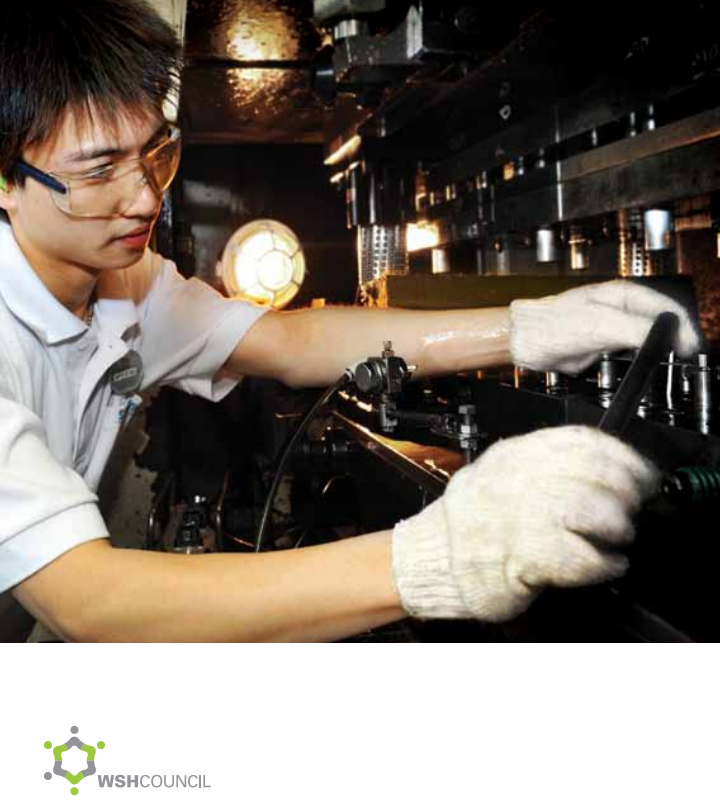

- 労働者の保護と安全基準の遵守を確保するために、安全な作業慣行を検討します。

- 潜在的な危険を特定、評価、軽減する上でのリスク管理の重要性を理解します。

- パワープレスを操作する人員の能力と認識を高めるためのトレーニングの役割について学びます。